Tesla high voltage safety is paramount for electric vehicle (EV) repair workshops due to the advanced and potentially dangerous high-voltage (HV) components powering critical functions like motors, batteries, and electronics. Best practices include comprehensive staff training, use of insulated tools, appropriate personal protective equipment (PPE), clutter-free workspaces, regular inspections, and adherence to Tesla's guidelines. Regular maintenance and specialized knowledge on battery packs and charging components are vital for preventing accidental discharge or short circuits, ensuring customer protection, and aligning with Tesla high voltage safety standards.

In today’s electric vehicle revolution, Tesla high voltage (HV) systems present both advanced technology and significant safety risks. Workshops play a crucial role in maintaining these vehicles, necessitating robust HV safety best practices. This article delves into understanding Tesla HV components and associated dangers, outlines critical workshop safety procedures and equipment requirements, and emphasizes the importance of ongoing training and maintenance for sustained safety standards.

- Understanding Tesla High Voltage Systems: Components and Risks

- Best Practices for Workshop Safety: Procedures and Equipment

- Training and Maintenance: Ensuring Long-Term Safety Standards

Understanding Tesla High Voltage Systems: Components and Risks

Tesla high voltage safety is paramount when working on these electric vehicles, as their advanced systems present unique challenges and risks. High-voltage (HV) components power critical functions, including motors, batteries, and electronics, making them not only essential but also potentially dangerous if mishandled. Understanding these systems requires recognizing key components like the battery pack, inverter, and charging ports. Each plays a vital role in the vehicle’s operation and must be treated with caution due to their high-energy nature.

Risks arise from direct contact or accidental exposure, which can lead to severe shocks or fires. Workshops engaging in auto body restoration or vehicle body shop services, especially those offering auto detailing, must prioritize Tesla high voltage safety protocols. This includes proper training for technicians, use of insulated tools and equipment, and adherence to manufacturer guidelines during repairs or modifications.

Best Practices for Workshop Safety: Procedures and Equipment

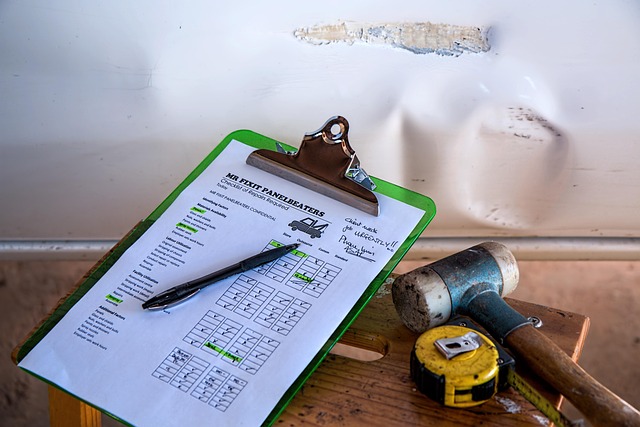

In any workshop engaging with Tesla high voltage safety, adhering to best practices is paramount. This involves ensuring proper training for all staff members on handling electric vehicle (EV) components, especially high-voltage systems. The focus should be on preventing accidental discharge or short circuits, as these can lead to severe electrical shocks or even vehicle collision repair risks. Utilization of insulated tools and equipment designed specifically for EV maintenance is crucial.

Workshops must invest in appropriate personal protective equipment (PPE) such as insulated gloves, boots, and safety goggles. Additionally, maintaining a clear, clutter-free workspace reduces the risk of tripping hazards and facilitates easy access to necessary tools, enhancing efficiency while ensuring the safety of workers in collision repair shops or vehicle body shops alike. Regular inspections and adherence to manufacturer guidelines for Tesla high voltage safety protocols are essential components of these best practices.

Training and Maintenance: Ensuring Long-Term Safety Standards

In ensuring Tesla high voltage safety, comprehensive training and regular maintenance are paramount. Workshops handling electric vehicle (EV) repairs must equip their staff with specialized knowledge on high-voltage systems, including battery packs and charging components. This involves rigorous training programs that teach not just technical aspects but also safety protocols specific to EV repairs. The focus should be on preventing accidents during work, as high voltage can pose significant risks.

Beyond initial training, consistent maintenance of tools and equipment is crucial. Just as a dent removal or auto collision center maintains their tools for optimal performance, so must workshops specializing in Tesla high voltage safety. Regular checks ensure that tools used in EV repairs remain safe and effective, thereby upholding the highest standards of safety over the long term. Auto body services offered should also be compatible with Tesla’s stringent safety measures to guarantee customer protection.

In light of the complex nature of Tesla high voltage systems and their increasing prevalence in workshops, adhering to stringent safety best practices is paramount. By understanding the components and risks associated with these systems, implementing robust procedures and utilizing specialized equipment, workshops can ensure a safe working environment for their employees. Continuous training and meticulous maintenance are equally vital to uphold safety standards over the long term, thereby fostering a culture of excellence and responsibility in Tesla high voltage handling.